The design of an IT network requires a thorough understanding of the organization's needs, careful planning, and precise execution.

This includes selecting the right hardware and software, ensuring security and scalability, and maintaining consistent performance and reliability. Common Components of IT Networks and Their Functions:

Routers:

Direct data packets between different networks.

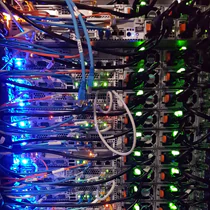

Switches:

Connect devices within the same network and manage data traffic at the data link layer.

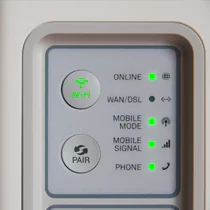

Access Points (APs):

Provide wireless connectivity for devices.

Hubs:

Basic devices that connect multiple Ethernet devices, primarily used in small networks.

Firewalls:

Monitor and control incoming and outgoing network traffic based on security rules.

Intrusion Detection/Prevention Systems (IDS/IPS):

Detect and prevent network security threats.

Network Access Management (NAM):

Regulates and controls access to network resources, preventing unauthorized access, reducing the risk of cyberattacks, and maintaining network security.

Ethernet Cables:

Standard cabling used for network connections.

Optical Fiber Cables:

High-speed data transmission cables for long distances and high bandwidth requirements.

Network Management Software:

Solutions for managing, monitoring, and configuring network devices.

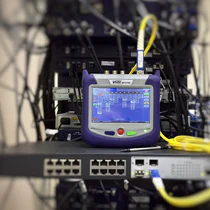

Performance Monitoring Tools:

Applications that track network performance metrics and generate alerts in case of issues.

Servers:

Provide various services such as DHCP, DNS, file sharing, and application hosting.

Storage Devices:

Network Attached Storage (NAS) and Storage Area Networks (SAN) for storing and retrieving data.

Building an Operational Technology (OT) network means creating a secure and efficient communication infrastructure for controlling and monitoring industrial processes and systems. OT networks differ from traditional IT networks in several ways, primarily due to the specific requirements of industrial environments, such as reliability, real-time performance, and security. Constructing an OT network requires careful planning, robust design, and precise execution, always tailored to the specific needs of the given industrial environment. Key Considerations in OT Networks:

Redundancy:

Implementing redundant pathways and backup systems to ensure continuous operation in case of failure.

High Availability:

Using technologies such as "hot standby," "failover," and "redundant controllers" to minimize downtime.

Segmentation:

Isolating OT networks from IT networks by using firewalls and demilitarized zones (DMZ) to restrict accessibility and reduce vulnerabilities.

Access Management:

Introducing strong access management mechanisms, including multi-level user authentication and role-based access control.

Encryption:

Encrypting data transmissions to prevent eavesdropping and manipulation.

Low Latency:

Optimizing the network to minimize latency, ensuring that control commands and feedback are processed quickly.

Deterministic Communication:

Applying protocols and technologies that support deterministic communication, where data packets are delivered within predictable timeframes.

Modular Design:

Deploying with scalability in mind, allowing for easy expansion and integration of devices and systems.

Standard Protocols:

Utilizing industry-standard protocols such as Modbus, OPC UA, and PROFINET for interoperability.

Hierarchical Design:

Implementing a hierarchical network architecture comprised of defined and segregated layers (field devices, control systems, supervisory systems) for efficient organization and management of data traffic.

Star, Ring, or Mesh Topology:

Choosing the appropriate network topology based on the specific requirements and size of industrial operations.

Sensors and Actuators:

Devices that collect data from the physical environment and execute control commands.

Programmable Logic Controllers (PLCs):

Controllers that automate industrial processes and communicate with field devices.

Industrial Switches and Routers:

Devices that manage data traffic within the OT network and are resistant to industrial conditions.

Firewalls and Gateways:

Security devices that protect the OT network from unauthorized access and cyber-attacks.

SCADA Systems:

Supervisory systems that provide centralized monitoring and control for industrial processes.

DCS (Distributed Control Systems):

Systems that manage manufacturing processes in real-time within complex industrial environments.

Modbus:

A widely used protocol for serial communication with industrial devices.

OPC UA (Open Platform Communications Unified Architecture):

A protocol for secure and reliable data exchange in industrial automation.

PROFINET:

An Ethernet-based protocol for real-time communication in industrial networks.